NdFeB Magnet

performance

With very high magnetic energy product and coercivity, known as “King of magnet”

COST performance

Ndfeb magnet is cost-effective compared to samarium cobalt.

NdFeB magnet

Neodymium magnets (also known as NdFeB, NIB or Neo magnet) have higher remanence, much higher coercivity and energy product.

Developed independently in 1984 by General Motors and Sumitomo Special Metals, neodymium magnets are the strongest type of permanent magnet available commercially.

application fileds

It is widely used in new energy vehicles, wind power generation, industrial motors, consumer electronics, medical devices and other fields.

Good mechanical properties

Good mechanical properties, easy to process into ring, round, square, tile and a variety of special-shaped sub-material products.

NdFeB Performance Table

| 牌号 Grade | 剩磁 (Br)Remanence | 内禀矫顽力(Hcj) Intrinic Coercivity | 矫顽力 (Hcb) Coercivity | 最大磁能积 (BH)max Max Energy Product | 密度 Density | 最大工作温度 Max Working Temperature |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T | kGs | kA/m | kOe | kA/m | kOe | kJ/m3 | MGOe | g/cm3 | ℃ | ||||||

| Max | Min | Max | Min | Min | Min | Min | Min | Max | Min | Max | Min | Min | |||

N | N56 | 1.51 | 1.47 | 15.1 | 14.7 | 876 | 11 | 836 | 10.5 | 454 | 414 | 57 | 52 | 7.5 | 80 |

| N54 | 1.49 | 1.45 | 14.9 | 14.5 | 955 | 12 | 836 | 10.5 | 437 | 406 | 55 | 51 | 7.5 | 80 | |

| N52 | 1.46 | 1.42 | 14.6 | 14.2 | 955 | 12 | 836 | 10.5 | 422 | 390 | 53 | 49 | 7.5 | 80 | |

| N50 | 1.44 | 1.39 | 14.4 | 13.9 | 955 | 12 | 860 | 10.8 | 406 | 374 | 51 | 47 | 7.5 | 80 | |

| N48 | 1.43 | 1.37 | 14.3 | 13.7 | 955 | 12 | 860 | 10.8 | 390 | 358 | 49 | 45 | 7.5 | 80 | |

| N45 | 1.37 | 1.32 | 13.7 | 13.2 | 955 | 12 | 860 | 10.8 | 366 | 342 | 46 | 43 | 7.5 | 80 | |

| N42 | 1.32 | 1.28 | 13.2 | 12.8 | 955 | 12 | 860 | 10.8 | 342 | 318 | 43 | 40 | 7.5 | 80 | |

| N40 | 1.28 | 1.25 | 12.8 | 12.5 | 955 | 12 | 860 | 10.8 | 326 | 302 | 41 | 38 | 7.5 | 80 | |

| N38 | 1.25 | 1.22 | 12.5 | 12.3 | 955 | 12 | 860 | 10.8 | 310 | 287 | 39 | 36 | 7.5 | 80 | |

| N35 | 1.22 | 1.17 | 12.2 | 11.7 | 955 | 12 | 860 | 10.8 | 287 | 263 | 36 | 33 | 7.5 | 80 | |

| N33 | 1.17 | 1.13 | 11.7 | 11.3 | 955 | 12 | 836 | 10.5 | 271 | 247 | 34 | 31 | 7.5 | 80 | |

| N30 | 1.13 | 1.08 | 11.3 | 10.8 | 955 | 12 | 796 | 10 | 247 | 223 | 31 | 28 | 7.5 | 80 | |

M | 56M | 1.5 | 1.46 | 15 | 14.6 | 1035 | 14 | 995 | 12.5 | 446 | 406 | 56 | 51 | 7.5 | 100 |

| 54M | 1.49 | 1.44 | 14.9 | 14.4 | 1114 | 14 | 1035 | 13 | 438 | 398 | 55 | 50 | 7.5 | 100 | |

| 52M | 1.46 | 1.42 | 14.6 | 14.2 | 1114 | 14 | 1035 | 13 | 422 | 382 | 53 | 49 | 7.5 | 100 | |

| 50M | 1.44 | 1.39 | 14.4 | 13.9 | 1114 | 14 | 1035 | 13 | 406 | 374 | 51 | 47 | 7.5 | 100 | |

| 48M | 1.42 | 1.37 | 14.2 | 13.7 | 1114 | 14 | 1027 | 12.9 | 390 | 358 | 49 | 45 | 7.5 | 100 | |

| 45M | 1.37 | 1.32 | 13.7 | 13.2 | 1114 | 14 | 995 | 12.5 | 366 | 342 | 46 | 43 | 7.5 | 100 | |

| 42M | 1.32 | 1.28 | 13.2 | 12.8 | 1114 | 14 | 955 | 12 | 342 | 318 | 43 | 40 | 7.5 | 100 | |

| 40M | 1.28 | 1.25 | 12.8 | 12.5 | 1114 | 14 | 923 | 11.6 | 326 | 302 | 41 | 38 | 7.5 | 100 | |

| 38M | 1.25 | 1.22 | 12.5 | 12.3 | 1114 | 14 | 899 | 11.3 | 310 | 287 | 39 | 36 | 7.5 | 100 | |

| 35M | 1.22 | 1.17 | 12.2 | 11.7 | 1114 | 14 | 868 | 10.9 | 287 | 263 | 36 | 33 | 7.5 | 100 | |

| 33M | 1.17 | 1.13 | 11.7 | 11.3 | 1114 | 14 | 836 | 10.5 | 271 | 247 | 34 | 31 | 7.5 | 100 | |

| 30M | 1.13 | 1.08 | 11.3 | 10.81 | 1141 | 14 | 796 | 10 | 247 | 223 | 31 | 28 | 7.5 | 100 | |

H | 54H | 1.49 | 1.44 | 14.9 | 14.4 | 1353 | 17 | 1075 | 13.5 | 438 | 398 | 55 | 50 | 7.5 | 120 |

| 52H | 1.46 | 1.42 | 14.6 | 14.2 | 1353 | 17 | 1059 | 13.3 | 422 | 382 | 53 | 48 | 7.5 | 120 | |

| 50H | 1.44 | 1.39 | 14.4 | 13.9 | 1353 | 17 | 1043 | 13.1 | 406 | 374 | 51 | 47 | 7.5 | 120 | |

| 48H | 1.42 | 1.36 | 14.2 | 13.6 | 1353 | 17 | 1027 | 12.9 | 390 | 358 | 49 | 45 | 7.5 | 120 | |

| 45H | 1.37 | 1.32 | 13.7 | 13.2 | 1353 | 17 | 995 | 12.5 | 366 | 342 | 46 | 43 | 7.5 | 120 | |

| 42H | 1.32 | 1.28 | 13.2 | 12.8 | 1353 | 17 | 955 | 12 | 342 | 318 | 43 | 40 | 7.5 | 120 | |

| 40H | 1.28 | 1.25 | 12.8 | 12.5 | 1353 | 17 | 923 | 11.6 | 326 | 302 | 41 | 38 | 7.5 | 120 | |

| 38H | 1.25 | 1.22 | 12.5 | 12.3 | 1353 | 17 | 899 | 11.3 | 310 | 287 | 39 | 36 | 7.5 | 120 | |

| 35H | 1.22 | 1.17 | 12.2 | 11.7 | 1353 | 17 | 868 | 10.9 | 287 | 263 | 36 | 33 | 7.5 | 120 | |

| 33H | 1.17 | 1.13 | 11.7 | 11.3 | 1353 | 17 | 836 | 10.5 | 271 | 247 | 34 | 31 | 7.5 | 120 | |

| 30H | 1.13 | 1.08 | 11.3 | 10.8 | 1353 | 17 | 796 | 10 | 247 | 223 | 31 | 28 | 7.5 | 120 | |

SH | 54SH | 1.49 | 1.44 | 14.9 | 14.4 | 1592 | 20 | 1075 | 13.5 | 438 | 398 | 55 | 50 | 7.5 | 150 |

| 52SH | 1.46 | 1.42 | 14.6 | 14.2 | 1592 | 20 | 1059 | 13.3 | 422 | 390 | 53 | 49 | 7.5 | 150 | |

| 50SH | 1.42 | 1.39 | 14.2 | 13.9 | 1592 | 20 | 1043 | 13.1 | 406 | 374 | 51 | 47 | 7.5 | 150 | |

| 48SH | 1.4 | 1.36 | 14 | 13.6 | 1592 | 20 | 1035 | 13 | 390 | 358 | 49 | 45 | 7.5 | 150 | |

| 45SH | 1.37 | 1.32 | 13.7 | 13.2 | 1592 | 20 | 995 | 12.5 | 366 | 342 | 46 | 43 | 7.5 | 150 | |

| 42SH | 1.32 | 1.28 | 13.2 | 12.8 | 1592 | 20 | 955 | 12 | 342 | 318 | 43 | 40 | 7.5 | 150 | |

| 40SH | 1.28 | 1.25 | 12.8 | 12.5 | 1592 | 20 | 939 | 11.8 | 326 | 302 | 41 | 38 | 7.5 | 150 | |

| 38SH | 1.25 | 1.22 | 12.5 | 12.2 | 1592 | 20 | 907 | 11.4 | 310 | 287 | 39 | 36 | 7.5 | 150 | |

| 35SH | 1.22 | 1.17 | 12.2 | 11.7 | 1592 | 20 | 876 | 11 | 287 | 263 | 36 | 33 | 7.5 | 150 | |

| 33SH | 1.17 | 1.13 | 11.7 | 11.3 | 1592 | 20 | 844 | 10.6 | 271 | 247 | 34 | 31 | 7.5 | 150 | |

| 30SH | 1.13 | 1.08 | 11.3 | 10.8 | 1592 | 20 | 804 | 10.1 | 247 | 223 | 31 | 28 | 7.5 | 150 | |

| UH | 48UH | 1.4 | 1.36 | 14 | 13.6 | 1910 | 24 | 1031 | 12.9 | 390 | 358 | 49 | 45 | 7.55 | 180 |

| 45UH | 1.36 | 1.32 | 13.6 | 13.2 | 1990 | 25 | 1003 | 12.6 | 366 | 342 | 46 | 43 | 7.55 | 180 | |

| 42UH | 1.32 | 1.28 | 13.2 | 12.8 | 1990 | 25 | 971 | 12.2 | 342 | 318 | 43 | 40 | 7.55 | 180 | |

| 40UH | 1.28 | 1.25 | 12.8 | 12.5 | 1990 | 25 | 923 | 11.6 | 326 | 302 | 41 | 38 | 7.55 | 180 | |

| 38UH | 1.25 | 1.22 | 12.5 | 12.2 | 1990 | 25 | 907 | 11.4 | 310 | 287 | 39 | 36 | 7.55 | 180 | |

| 35UH | 1.22 | 1.17 | 12.2 | 11.7 | 1990 | 25 | 860 | 10.8 | 287 | 263 | 36 | 33 | 7.55 | 180 | |

| 33UH | 1.17 | 1.13 | 11.7 | 11.3 | 1990 | 25 | 852 | 10.7 | 271 | 247 | 34 | 31 | 7.55 | 180 | |

| 30UH | 1.13 | 1.08 | 11.3 | 10.8 | 1990 | 25 | 812 | 10.2 | 247 | 223 | 31 | 28 | 7.55 | 180 | |

| EH | 45EH | 1.36 | 1.32 | 13.6 | 13.2 | 2308 | 29 | 1003 | 12.6 | 366 | 342 | 46 | 43 | 7.6 | 200 |

| 42EH | 1.32 | 1.28 | 13.2 | 12.8 | 2388 | 30 | 970 | 12.2 | 342 | 318 | 43 | 40 | 7.6 | 200 | |

| 40EH | 1.28 | 1.25 | 12.8 | 12.5 | 2388 | 30 | 947 | 11.9 | 326 | 302 | 41 | 38 | 7.6 | 200 | |

| 38EH | 1.25 | 1.22 | 12.5 | 12.2 | 2388 | 30 | 915 | 11.5 | 310 | 287 | 39 | 36 | 7.6 | 200 | |

| 35EH | 1.22 | 1.17 | 12.2 | 11.7 | 2388 | 30 | 884 | 11.1 | 287 | 263 | 36 | 33 | 7.6 | 200 | |

| 33EH | 1.17 | 1.13 | 11.7 | 11.3 | 2388 | 30 | 860 | 10.8 | 271 | 247 | 34 | 31 | 7.6 | 200 | |

| 30EH | 1.13 | 1.08 | 11.3 | 10.8 | 2388 | 30 | 820 | 10.3 | 247 | 223 | 31 | 28 | 7.6 | 200 | |

| AH | 40AH | 1.28 | 1.25 | 12.8 | 12.5 | 2706 | 34 | 947 | 11.9 | 326 | 302 | 41 | 38 | 7.6 | 230 |

| 38AH | 1.25 | 1.22 | 12.5 | 12.2 | 2786 | 35 | 915 | 11.5 | 310 | 287 | 39 | 36 | 7.6 | 230 | |

| 35AH | 1.2 | 1.17 | 12 | 11.7 | 2786 | 35 | 883 | 11.1 | 287 | 263 | 36 | 33 | 7.6 | 230 | |

| 33AH | 1.17 | 1.11 | 11.7 | 11.1 | 2786 | 35 | 844 | 10.6 | 271 | 239 | 34 | 31 | 7.6 | 230 | |

| 30AH | 1.13 | 1.07 | 11.3 | 10.7 | 2786 | 35 | 812 | 10.2 | 247 | 215 | 31 | 27 | 7.6 | 230 | |

| 28AH | 1.09 | 1.02 | 10.9 | 10.2 | 2786 | 35 | 772 | 9.7 | 231 | 199 | 29 | 25 | 7.6 | 230 | |

| TH | 35TH | 1.22 | 1.17 | 12.2 | 11.7 | 3102 | 39 | 867 | 10.9 | 287 | 263 | 36 | 33 | 7.6 | 250 |

| 33TH | 1.17 | 1.11 | 11.7 | 11.1 | 3182 | 40 | 851 | 10.7 | 271 | 239 | 34 | 31 | 7.6 | 250 | |

| 30TH | 1.13 | 1.08 | 11.3 | 10.8 | 3182 | 40 | 820 | 10.3 | 247 | 223 | 31 | 28 | 7.6 | 250 | |

Physical Properties of sintered NdFeB

| Physical Properties of Sintered NdFeB | |

|---|---|

| Reversible Temp coeff. Of Br | -0.09~-0.11%/℃ |

| Reversible Temp coeff. Of Hcj | -0.45~-0.75%/℃ |

| Density | 7.4~7.7g/cm³ |

| Vickers Hardness | 500~600HV |

| Compressive Strength | 1000~1500MPa |

| Specific Heat | 0.12Kcal(Kg.℃) |

| Young Modulus | 150~200GPa |

| Poisson’s Ratio | 0.24 |

| Curie Temperature | 310~350℃ |

| Electrical Resistivity | 1.4~1.6μΩ·m |

| Tensile Strength | 80~90MPa |

| Coefficient of Thermal Expansion | (1-4)×10-6℃ |

| Pyroconductivity | 8~10W/(m.K) |

| Stiffness | 0.64N/m² |

| Compression Ratio | 9.8*10-12m2/N |

| Relative Permeability | 1.02~1.06 |

| Standard:GB/T 13560-2009 | |

Manufacturing Process

Our technical capability

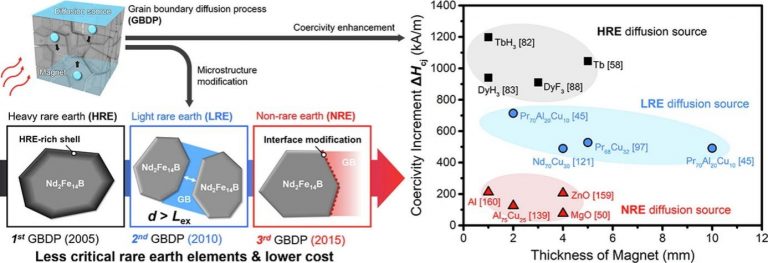

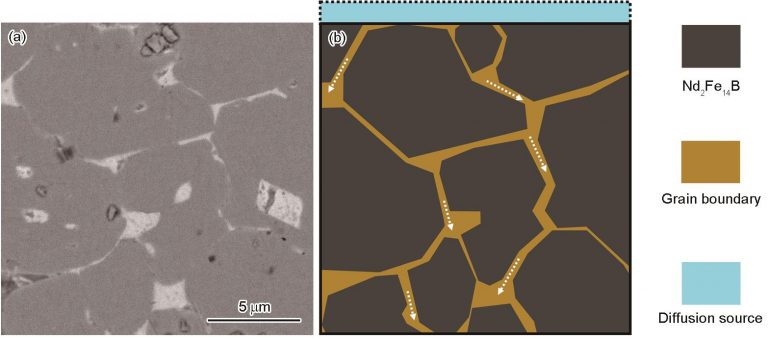

Grain boundary diffusion process(GBDP)

Ndfeb permanent magnet has a wide range of applications in the fields of new energy, information communication and intelligent manufacturing. The high temperature performance and coercivity of NdFeb magnets are required by electric vehicle driving motor and wind power system generator. Heavy rare earths Tb and Dy can significantly improve the anisotropic field of NdFeb magnets, but reduce the remanence and increase the cost. Grain boundary diffusion technology, which appeared in the early 21st century, is an important development in the field of rare earth permanent magnet manufacturing. By infiltrating heavy rare earth elements or rare earth alloys into the magnet through grain boundary diffusion, it can effectively improve the coercivity of the magnet, greatly reduce the content of heavy rare earth, and improve the cost performance.

advantages of GBDP

Grain boundary diffusion technology can reduce the consumption of heavy rare earth and effectively save heavy rare earth resources. Reduce the cost of magnet production, improve the comprehensive cost performance of products. Compared with the traditional process, the grain boundary diffusion process can produce magnets with higher comprehensive properties, such as52SH、52UH、45EH、42AH,38TH(VH);some of the magnets Hcj(kOe)+(BH)max(MGOe)>82.

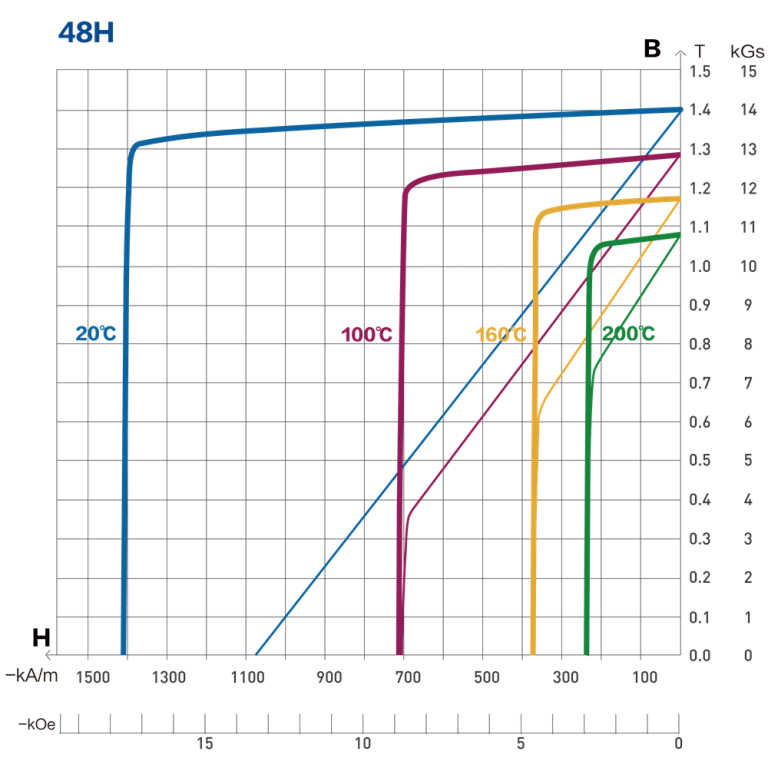

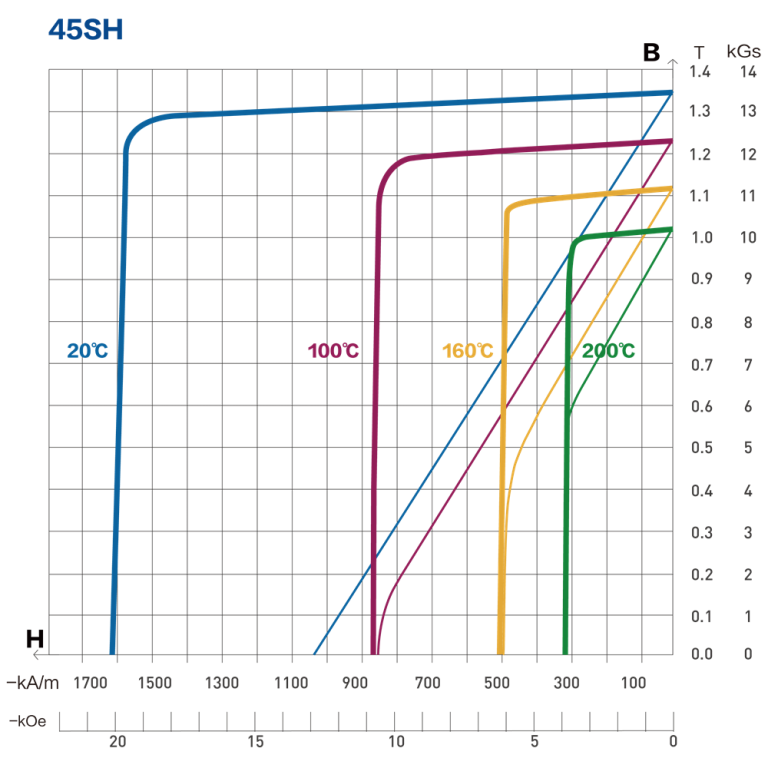

Demagnetizing Curve

Surface Treatment

Galvanization

Nickel Plating

Epoxy

Gold Plating

| Surface treatment Type | Plating code | Color | Thickness | SST | Temp. & Humi. | High-pressure accelerated aging test | Use Temp. |

|---|---|---|---|---|---|---|---|

| Blue and white zinc | Zn.L | Blue and white | 4-15μm | ≥24h | / | / | ≤160℃ |

| Color zinc | Zn.C | Colourful | 4-15μm | ≥48h | / | / | ≤160℃ |

| Nickel copper nickel(barrel plating) | NiCuNi | Silver | 5-20μm | ≥48h | 500h | 48h | ≤200℃ |

| Nickel copper nickel (hang plating) | NiCuNi | Silver | 5-20μm | ≥24h | 500h | 48h | ≤200℃ |

| Nickel Copper Nickel + Tin | NiCuNi+Sn | Silver white | 5-20μm | ≥72h | 500h | 96h | ≤200℃ |

| Nickel+tin | Ni+Sn | Silver white | 5-20μm | ≥72h | 500h | 96h | ≤200℃ |

| Nickel+silver | Ni+Ag | Silver | 5-20μm | ≥72h | 72h | 96h | ≤160℃ |

| Nickel+gold | Ni+Au | Golden | 5-20μm | ≥72h | 500h | 96h | ≤200℃ |

| Nickel + chemical nickel (hang plating) | Ni+Ap.Ni | Silver | 3-20μm | ≥24h | 500h | 48h | ≤200℃ |

| Nickel + chemical nickel (barrel plating) | Ni+Ap.Ni | Silver | 3-20μm | ≥72h | 500h | 48h | ≤200℃ |

| Epoxy | Epoxy | Black, grey | 10-30μm | ≥72h | 72h | 200h | ≤160℃ |

| Nickel copper + epoxy | NiCu+Epoxy | Black, grey | 20-40μm | ≥500h | 500h | 200h | ≤160℃ |

| Aluminum | PVD.Al | Silver white | 2-15μm | ≥100h | 500h | 200h | ≤400℃ |

| Aluminum + epoxy | PVD.Al+Epoxy | black, grey | 15-30μm | ≥200h | 500h | 200h | ≤160℃ |

| Parylene | Parylene | Colorless and transparent | 20-50 | ≥220h | 500h | 48h | ≤120℃ |