钕铁硼磁钢

性能

具有极高的磁能积和矫顽力,被称为“磁王”,使仪器仪表、电声电机、磁选等设备实现小型化、轻量化、轻薄化。

性价比

相比于钐钴,钕铁硼具有较高的性价比。

应用领域

广泛应用于新能源汽车,风力发电,工业电机,消费电子,医疗器械等领域。

良好的机械特性

良好的机械性能,容易加工成环形、圆形、方型、瓦型以及各种异形的次材产品。

钕铁硼性能表

| 牌号 Grade | 剩磁 (Br)Remanence | 内禀矫顽力(Hcj) Intrinic Coercivity | 矫顽力 (Hcb) Coercivity | 最大磁能积 (BH)max Max Energy Product | 密度 Density | 最大工作温度 Max Working Temperature |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T | kGs | kA/m | kOe | kA/m | kOe | kJ/m3 | MGOe | g/cm3 | ℃ | ||||||

| Max | Min | Max | Min | Min | Min | Min | Min | Max | Min | Max | Min | Min | |||

N | N56 | 1.51 | 1.47 | 15.1 | 14.7 | 876 | 11 | 836 | 10.5 | 454 | 414 | 57 | 52 | 7.5 | 80 |

| N54 | 1.49 | 1.45 | 14.9 | 14.5 | 955 | 12 | 836 | 10.5 | 437 | 406 | 55 | 51 | 7.5 | 80 | |

| N52 | 1.46 | 1.42 | 14.6 | 14.2 | 955 | 12 | 836 | 10.5 | 422 | 390 | 53 | 49 | 7.5 | 80 | |

| N50 | 1.44 | 1.39 | 14.4 | 13.9 | 955 | 12 | 860 | 10.8 | 406 | 374 | 51 | 47 | 7.5 | 80 | |

| N48 | 1.43 | 1.37 | 14.3 | 13.7 | 955 | 12 | 860 | 10.8 | 390 | 358 | 49 | 45 | 7.5 | 80 | |

| N45 | 1.37 | 1.32 | 13.7 | 13.2 | 955 | 12 | 860 | 10.8 | 366 | 342 | 46 | 43 | 7.5 | 80 | |

| N42 | 1.32 | 1.28 | 13.2 | 12.8 | 955 | 12 | 860 | 10.8 | 342 | 318 | 43 | 40 | 7.5 | 80 | |

| N40 | 1.28 | 1.25 | 12.8 | 12.5 | 955 | 12 | 860 | 10.8 | 326 | 302 | 41 | 38 | 7.5 | 80 | |

| N38 | 1.25 | 1.22 | 12.5 | 12.3 | 955 | 12 | 860 | 10.8 | 310 | 287 | 39 | 36 | 7.5 | 80 | |

| N35 | 1.22 | 1.17 | 12.2 | 11.7 | 955 | 12 | 860 | 10.8 | 287 | 263 | 36 | 33 | 7.5 | 80 | |

| N33 | 1.17 | 1.13 | 11.7 | 11.3 | 955 | 12 | 836 | 10.5 | 271 | 247 | 34 | 31 | 7.5 | 80 | |

| N30 | 1.13 | 1.08 | 11.3 | 10.8 | 955 | 12 | 796 | 10 | 247 | 223 | 31 | 28 | 7.5 | 80 | |

M | 56M | 1.5 | 1.46 | 15 | 14.6 | 1035 | 14 | 995 | 12.5 | 446 | 406 | 56 | 51 | 7.5 | 100 |

| 54M | 1.49 | 1.44 | 14.9 | 14.4 | 1114 | 14 | 1035 | 13 | 438 | 398 | 55 | 50 | 7.5 | 100 | |

| 52M | 1.46 | 1.42 | 14.6 | 14.2 | 1114 | 14 | 1035 | 13 | 422 | 382 | 53 | 49 | 7.5 | 100 | |

| 50M | 1.44 | 1.39 | 14.4 | 13.9 | 1114 | 14 | 1035 | 13 | 406 | 374 | 51 | 47 | 7.5 | 100 | |

| 48M | 1.42 | 1.37 | 14.2 | 13.7 | 1114 | 14 | 1027 | 12.9 | 390 | 358 | 49 | 45 | 7.5 | 100 | |

| 45M | 1.37 | 1.32 | 13.7 | 13.2 | 1114 | 14 | 995 | 12.5 | 366 | 342 | 46 | 43 | 7.5 | 100 | |

| 42M | 1.32 | 1.28 | 13.2 | 12.8 | 1114 | 14 | 955 | 12 | 342 | 318 | 43 | 40 | 7.5 | 100 | |

| 40M | 1.28 | 1.25 | 12.8 | 12.5 | 1114 | 14 | 923 | 11.6 | 326 | 302 | 41 | 38 | 7.5 | 100 | |

| 38M | 1.25 | 1.22 | 12.5 | 12.3 | 1114 | 14 | 899 | 11.3 | 310 | 287 | 39 | 36 | 7.5 | 100 | |

| 35M | 1.22 | 1.17 | 12.2 | 11.7 | 1114 | 14 | 868 | 10.9 | 287 | 263 | 36 | 33 | 7.5 | 100 | |

| 33M | 1.17 | 1.13 | 11.7 | 11.3 | 1114 | 14 | 836 | 10.5 | 271 | 247 | 34 | 31 | 7.5 | 100 | |

| 30M | 1.13 | 1.08 | 11.3 | 10.81 | 1141 | 14 | 796 | 10 | 247 | 223 | 31 | 28 | 7.5 | 100 | |

H | 54H | 1.49 | 1.44 | 14.9 | 14.4 | 1353 | 17 | 1075 | 13.5 | 438 | 398 | 55 | 50 | 7.5 | 120 |

| 52H | 1.46 | 1.42 | 14.6 | 14.2 | 1353 | 17 | 1059 | 13.3 | 422 | 382 | 53 | 48 | 7.5 | 120 | |

| 50H | 1.44 | 1.39 | 14.4 | 13.9 | 1353 | 17 | 1043 | 13.1 | 406 | 374 | 51 | 47 | 7.5 | 120 | |

| 48H | 1.42 | 1.36 | 14.2 | 13.6 | 1353 | 17 | 1027 | 12.9 | 390 | 358 | 49 | 45 | 7.5 | 120 | |

| 45H | 1.37 | 1.32 | 13.7 | 13.2 | 1353 | 17 | 995 | 12.5 | 366 | 342 | 46 | 43 | 7.5 | 120 | |

| 42H | 1.32 | 1.28 | 13.2 | 12.8 | 1353 | 17 | 955 | 12 | 342 | 318 | 43 | 40 | 7.5 | 120 | |

| 40H | 1.28 | 1.25 | 12.8 | 12.5 | 1353 | 17 | 923 | 11.6 | 326 | 302 | 41 | 38 | 7.5 | 120 | |

| 38H | 1.25 | 1.22 | 12.5 | 12.3 | 1353 | 17 | 899 | 11.3 | 310 | 287 | 39 | 36 | 7.5 | 120 | |

| 35H | 1.22 | 1.17 | 12.2 | 11.7 | 1353 | 17 | 868 | 10.9 | 287 | 263 | 36 | 33 | 7.5 | 120 | |

| 33H | 1.17 | 1.13 | 11.7 | 11.3 | 1353 | 17 | 836 | 10.5 | 271 | 247 | 34 | 31 | 7.5 | 120 | |

| 30H | 1.13 | 1.08 | 11.3 | 10.8 | 1353 | 17 | 796 | 10 | 247 | 223 | 31 | 28 | 7.5 | 120 | |

SH | 54SH | 1.49 | 1.44 | 14.9 | 14.4 | 1592 | 20 | 1075 | 13.5 | 438 | 398 | 55 | 50 | 7.5 | 150 |

| 52SH | 1.46 | 1.42 | 14.6 | 14.2 | 1592 | 20 | 1059 | 13.3 | 422 | 390 | 53 | 49 | 7.5 | 150 | |

| 50SH | 1.42 | 1.39 | 14.2 | 13.9 | 1592 | 20 | 1043 | 13.1 | 406 | 374 | 51 | 47 | 7.5 | 150 | |

| 48SH | 1.4 | 1.36 | 14 | 13.6 | 1592 | 20 | 1035 | 13 | 390 | 358 | 49 | 45 | 7.5 | 150 | |

| 45SH | 1.37 | 1.32 | 13.7 | 13.2 | 1592 | 20 | 995 | 12.5 | 366 | 342 | 46 | 43 | 7.5 | 150 | |

| 42SH | 1.32 | 1.28 | 13.2 | 12.8 | 1592 | 20 | 955 | 12 | 342 | 318 | 43 | 40 | 7.5 | 150 | |

| 40SH | 1.28 | 1.25 | 12.8 | 12.5 | 1592 | 20 | 939 | 11.8 | 326 | 302 | 41 | 38 | 7.5 | 150 | |

| 38SH | 1.25 | 1.22 | 12.5 | 12.2 | 1592 | 20 | 907 | 11.4 | 310 | 287 | 39 | 36 | 7.5 | 150 | |

| 35SH | 1.22 | 1.17 | 12.2 | 11.7 | 1592 | 20 | 876 | 11 | 287 | 263 | 36 | 33 | 7.5 | 150 | |

| 33SH | 1.17 | 1.13 | 11.7 | 11.3 | 1592 | 20 | 844 | 10.6 | 271 | 247 | 34 | 31 | 7.5 | 150 | |

| 30SH | 1.13 | 1.08 | 11.3 | 10.8 | 1592 | 20 | 804 | 10.1 | 247 | 223 | 31 | 28 | 7.5 | 150 | |

| UH | 48UH | 1.4 | 1.36 | 14 | 13.6 | 1910 | 24 | 1031 | 12.9 | 390 | 358 | 49 | 45 | 7.55 | 180 |

| 45UH | 1.36 | 1.32 | 13.6 | 13.2 | 1990 | 25 | 1003 | 12.6 | 366 | 342 | 46 | 43 | 7.55 | 180 | |

| 42UH | 1.32 | 1.28 | 13.2 | 12.8 | 1990 | 25 | 971 | 12.2 | 342 | 318 | 43 | 40 | 7.55 | 180 | |

| 40UH | 1.28 | 1.25 | 12.8 | 12.5 | 1990 | 25 | 923 | 11.6 | 326 | 302 | 41 | 38 | 7.55 | 180 | |

| 38UH | 1.25 | 1.22 | 12.5 | 12.2 | 1990 | 25 | 907 | 11.4 | 310 | 287 | 39 | 36 | 7.55 | 180 | |

| 35UH | 1.22 | 1.17 | 12.2 | 11.7 | 1990 | 25 | 860 | 10.8 | 287 | 263 | 36 | 33 | 7.55 | 180 | |

| 33UH | 1.17 | 1.13 | 11.7 | 11.3 | 1990 | 25 | 852 | 10.7 | 271 | 247 | 34 | 31 | 7.55 | 180 | |

| 30UH | 1.13 | 1.08 | 11.3 | 10.8 | 1990 | 25 | 812 | 10.2 | 247 | 223 | 31 | 28 | 7.55 | 180 | |

| EH | 45EH | 1.36 | 1.32 | 13.6 | 13.2 | 2308 | 29 | 1003 | 12.6 | 366 | 342 | 46 | 43 | 7.6 | 200 |

| 42EH | 1.32 | 1.28 | 13.2 | 12.8 | 2388 | 30 | 970 | 12.2 | 342 | 318 | 43 | 40 | 7.6 | 200 | |

| 40EH | 1.28 | 1.25 | 12.8 | 12.5 | 2388 | 30 | 947 | 11.9 | 326 | 302 | 41 | 38 | 7.6 | 200 | |

| 38EH | 1.25 | 1.22 | 12.5 | 12.2 | 2388 | 30 | 915 | 11.5 | 310 | 287 | 39 | 36 | 7.6 | 200 | |

| 35EH | 1.22 | 1.17 | 12.2 | 11.7 | 2388 | 30 | 884 | 11.1 | 287 | 263 | 36 | 33 | 7.6 | 200 | |

| 33EH | 1.17 | 1.13 | 11.7 | 11.3 | 2388 | 30 | 860 | 10.8 | 271 | 247 | 34 | 31 | 7.6 | 200 | |

| 30EH | 1.13 | 1.08 | 11.3 | 10.8 | 2388 | 30 | 820 | 10.3 | 247 | 223 | 31 | 28 | 7.6 | 200 | |

| AH | 40AH | 1.28 | 1.25 | 12.8 | 12.5 | 2706 | 34 | 947 | 11.9 | 326 | 302 | 41 | 38 | 7.6 | 230 |

| 38AH | 1.25 | 1.22 | 12.5 | 12.2 | 2786 | 35 | 915 | 11.5 | 310 | 287 | 39 | 36 | 7.6 | 230 | |

| 35AH | 1.2 | 1.17 | 12 | 11.7 | 2786 | 35 | 883 | 11.1 | 287 | 263 | 36 | 33 | 7.6 | 230 | |

| 33AH | 1.17 | 1.11 | 11.7 | 11.1 | 2786 | 35 | 844 | 10.6 | 271 | 239 | 34 | 31 | 7.6 | 230 | |

| 30AH | 1.13 | 1.07 | 11.3 | 10.7 | 2786 | 35 | 812 | 10.2 | 247 | 215 | 31 | 27 | 7.6 | 230 | |

| 28AH | 1.09 | 1.02 | 10.9 | 10.2 | 2786 | 35 | 772 | 9.7 | 231 | 199 | 29 | 25 | 7.6 | 230 | |

| TH | 35TH | 1.22 | 1.17 | 12.2 | 11.7 | 3102 | 39 | 867 | 10.9 | 287 | 263 | 36 | 33 | 7.6 | 250 |

| 33TH | 1.17 | 1.11 | 11.7 | 11.1 | 3182 | 40 | 851 | 10.7 | 271 | 239 | 34 | 31 | 7.6 | 250 | |

| 30TH | 1.13 | 1.08 | 11.3 | 10.8 | 3182 | 40 | 820 | 10.3 | 247 | 223 | 31 | 28 | 7.6 | 250 | |

烧结钕铁硼物理性能

| 烧结钕铁硼物理性能 Physical Properties of Sintered NdFeB |

|

|---|---|

| Br可逆温度系数 Reversible Temp coeff. Of Br | -0.09~-0.11%/℃ |

| Hcj可逆温度系数 Reversible Temp coeff. Of Hcj | -0.45~-0.75%/℃ |

| 密度 Density | 7.4~7.7g/cm³ |

| 维氏硬度 Vickers Hardness | 500~600HV |

| 抗压强度 Compressive Strength | 1000~1500MPa |

| 比热 Specific Heat | 0.12Kcal(Kg.℃) |

| 杨氏模量 Young Modulus | 150~200GPa |

| 泊松比 Poisson’s Ratio | 0.24 |

| 居里温度 Curie Temperature | 310~350℃ |

| 电阻率 Electrical Resistivity | 1.4~1.6μΩ·m |

| 抗拉强度 Tensile Strength | 80~90MPa |

| 热膨胀系数 Coefficient of Thermal Expansion | (1-4)×10-6℃ |

| 热传导率 Pyroconductivity | 8~10W/(m.K) |

| 刚度 Stiffness | 0.64N/m² |

| 压缩率 Compression Ratio | 9.8*10-12m2/N |

| 相对磁导率 Relative Permeability | 1.02~1.06 |

| 注:参考标准:GB/T 13560-2009 | |

制造流程

1-weighing

1-配料

2-melting

2-熔炼

3-jet milling

3-气流磨制粉

4-molding

4-压制成型

5-sinterring

烧结

6-magnetic testing

6-磁性能检测

7-machining

7-机械加工

8-plating(if needed)

8-电镀

9-magnetizing and packing

9-充磁包装

10-shipping

10-发货

技术能力

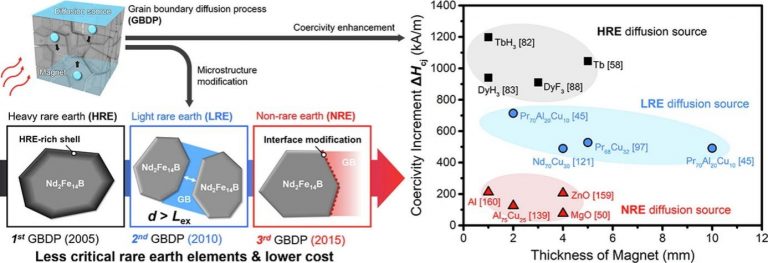

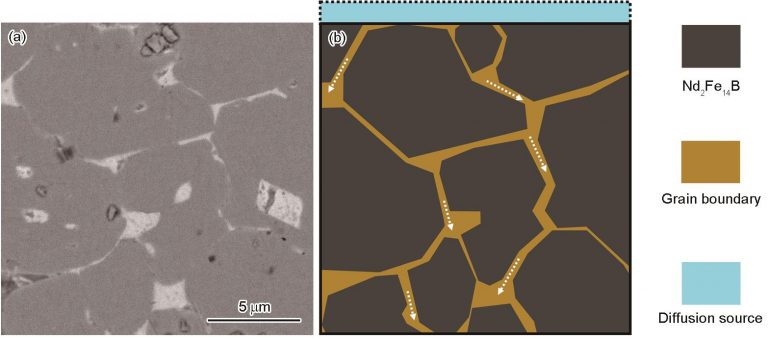

晶界扩散介绍

钕铁硼永磁在新能源、信息通讯和智能制造等领域有着广泛的应用。电动汽车驱动电机、风电系统发电机等对钕铁硼磁体的高温性能和矫顽力提出了更高的要求。重稀土Tb和Dy可以显著提高钕铁硼磁体的各向异性场,但降低了剩磁,增加了成本。21世纪初出现的晶界扩散技术是稀土永磁制造领域的一项重大进展。它通过将重稀土元素或稀土合金以晶界扩散的方式渗透入磁体,在有效提高磁体矫顽力的同时,大幅降低重稀土含量,提高性价比。

晶界扩散优势

晶界扩散技术可减少重稀土用量,有效节约重稀土资源;降低磁体生产成本,提高产品的综合性价比。 针对同样性能的磁体,晶界扩散工艺技术比传统工艺技术的重稀土使用量更少与传统工艺相比,晶界扩散工艺能制备出更高综合性能的磁体,如52SH、52UH、45EH、42AH,38TH(VH);其中部分磁体的Hcj(kOe)+(BH)max(MGOe)>82。

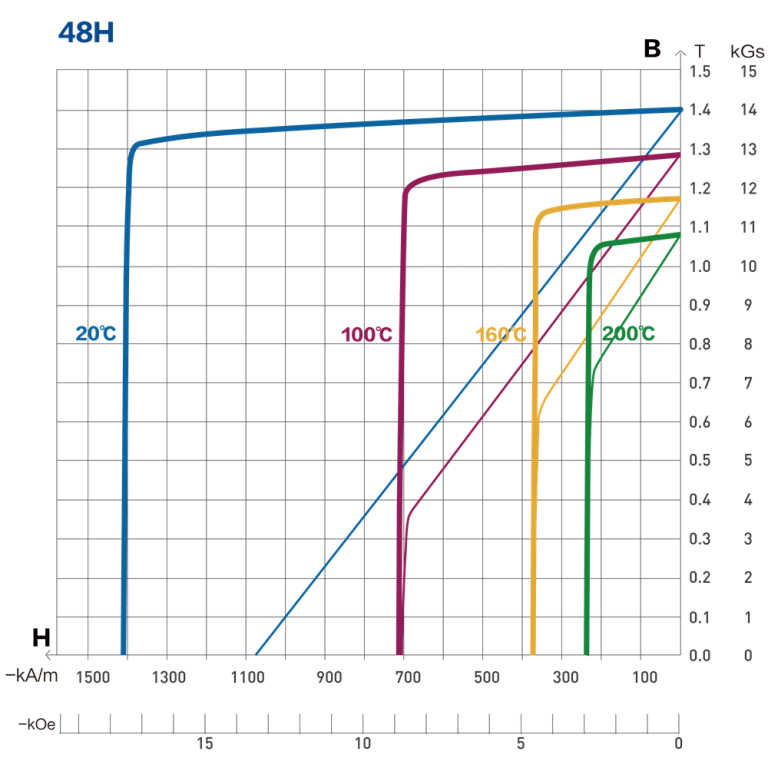

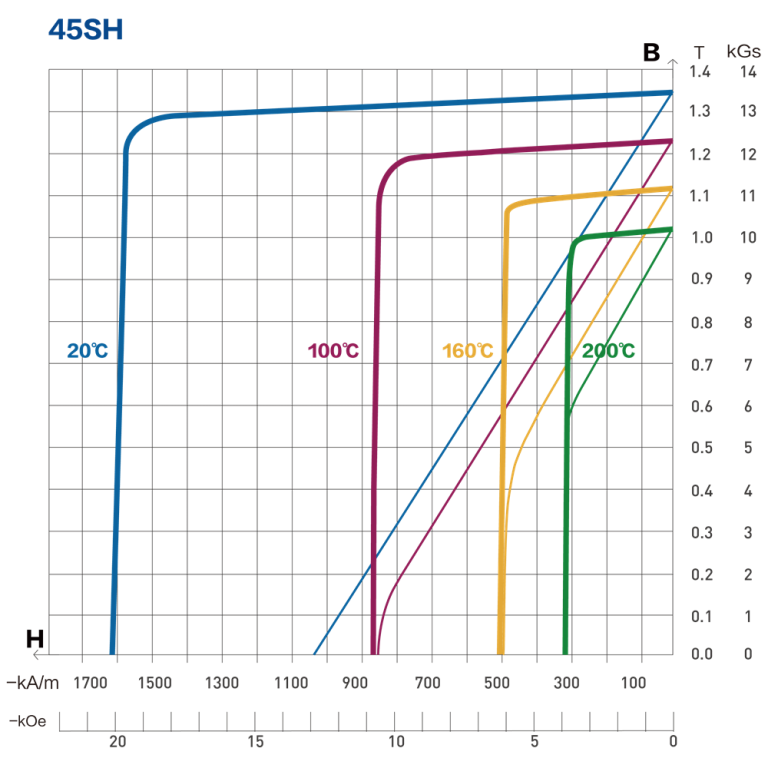

退磁曲线

镀层介绍

镀锌

镀镍

环氧

镀金

| 表面处理 | 镀层代号 | 颜色 | 镀层厚度 | 中性盐雾试验 | 湿热试验 | 高压加速老化试验 | 使用温度 |

|---|---|---|---|---|---|---|---|

| 蓝白锌 | Zn.L | 蓝白色 | 4-15μm | ≥24h | / | / | ≤160℃ |

| 彩锌 | Zn.C | 多彩色 | 4-15μm | ≥48h | / | / | ≤160℃ |

| 镍铜镍(滚镀) | NiCuNi | 银色 | 5-20μm | ≥48h | 500h | 48h | ≤200℃ |

| 镍铜镍(挂镀) | NiCuNi | 银色 | 5-20μm | ≥24h | 500h | 48h | ≤200℃ |

| 镍铜镍+锡 | NiCuNi+Sn | 银白色 | 5-20μm | ≥72h | 500h | 96h | ≤200℃ |

| 镍+锡 | Ni+Sn | 银白色 | 5-20μm | ≥72h | 500h | 96h | ≤200℃ |

| 镍+银 | Ni+Ag | 银色 | 5-20μm | ≥72h | 72h | 96h | ≤160℃ |

| 镍+金 | Ni+Au | 金黄色 | 5-20μm | ≥72h | 500h | 96h | ≤200℃ |

| 镍+化学镍(挂镀) | Ni+Ap.Ni | 银色 | 3-20μm | ≥24h | 500h | 48h | ≤200℃ |

| 镍+化学镍(滚镀) | Ni+Ap.Ni | 银色 | 3-20μm | ≥72h | 500h | 48h | ≤200℃ |

| 环氧 | Epoxy | 黑色/灰色 | 10-30μm | ≥72h | 72h | 200h | ≤160℃ |

| 镍铜+环氧 | NiCu+Epoxy | 黑色/灰色 | 20-40μm | ≥500h | 500h | 200h | ≤160℃ |

| 铝 | PVD.Al | 银白色 | 2-15μm | ≥100h | 500h | 200h | ≤400℃ |

| 铝+环氧 | PVD.Al+Epoxy | 黑色/灰色 | 15-30μm | ≥200h | 500h | 200h | ≤160℃ |

| 派瑞林 | Parylene | 无色透明 | 20-50 | ≥220h | 500h | 48h | ≤120℃ |